I. Market Demand and Material Properties

As the global automotive industry shifts toward lightweighting, personalization, and environmental friendliness, color-coated coil, a composite material that combines functionality and decorative features, is playing an increasingly important role in the automotive industry. Its core advantages are:

Lightweight and High Strength

Color-coated coil uses galvanized or aluminum sheet as a substrate, applying a zinc-aluminum coating through hot-dip or electroplating. This maintains the metal's mechanical strength while reducing weight by over 30% compared to traditional steel. For example, the Tesla Model Y uses galvanized color-coated coil for its battery pack housing, reducing weight by up to 45kg per case while maintaining pressure resistance.

Weather Resistance and Environmental Protection

Fluorocarbon-coated color-coated coil has passed the ISO 4892-2 xenon lamp weathering test and remains colorfast for five years under the strong UV rays of Hainan Island. BMW Group's Munich plant uses water-based polyester-coated color-coated coil, which reduces VOC emissions by 82% compared to traditional spray coating processes, complying with the EU ELV directive.

Integration of Decor and Function

Metallic glitter paint-effect coated coils simulate the texture of brushed aluminum, while nano-oleophobic coatings enable instant grease removal in the BYD Han EV's interior. A more advanced photocatalytic coating has been applied to the Nissan Ariya, degrading formaldehyde in the vehicle through a TiO₂ coating.

II. Typical Application Scenarios and Case Studies

1. Exterior Panel System

High-End Vehicle Exterior

The Lexus LS series uses 25μm thick galvanized color-coated coils for its hood, combined with a metallic glitter paint process. While maintaining an ultra-thin 0.3mm substrate, its stone impact resistance has been verified through a 45° fold test.

New Energy Vehicle Personalization

The Xpeng P7 uses INTEGO color film for body customization. Using the Epson SureColor S80680 printer, it achieves a resolution of 1440dpi on a 0.5mm thick PET substrate, improving application efficiency by 60%.

2. Interior and Functional Components

Stain-Resistant Flooring System

Zhengzhou Yutong Bus utilizes dark gray, scratch-resistant color-coated coil in its bus models. The coating achieves a hardness of 2H and remains scratch-free after 5,000 shoe friction tests, reducing maintenance costs by 40% compared to traditional PVC flooring.

Anti-Corrosion Structural Parts

The FAW Jiefang J7 heavy-duty truck's fuel tank exterior utilizes anti-static color-coated coil. The surface resistivity is controlled at 10⁶-10⁹Ω, passing the GB/T 1410-2009 standard test, effectively preventing safety hazards caused by static electricity accumulation.

3. Customized Special Vehicles

Refrigerated Truck Composite Panels

CIMC vehicles utilize polyurethane sandwich color-coated panels, with a base material of TS350GD+Z galvanized coil. The insulation layer has a thermal conductivity of ≤0.024W/(m·K) and maintains a deformation rate of <0.2% in a -20°C cold storage environment.

High-temperature-resistant components for fire trucks

XCMG Fire Protection uses TS280GD fluorocarbon-coated color-coated coils to manufacture aerial ladder supports. These coils have passed the GB/T 1735-2009 heat resistance test and can operate continuously at 150°C for 72 hours without coating detachment.

III. Customized Solution System

1. Material-Level Customization

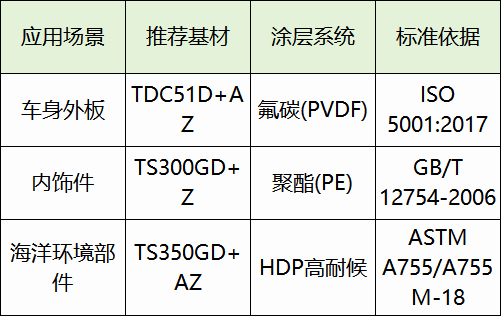

Substrate Selection Matrix

Functional Coating Development

For new energy vehicle battery packs, we have developed a composite coating that combines electromagnetic shielding and thermal conductivity, achieving a shielding effectiveness of 60dB (10MHz-1GHz) and a thermal resistance of <0.1°C·cm²/W.

2. Process-Level Customization

Stamping Optimization

Through finite element analysis and simulation, we adjusted the crystal structure of the galvanized coils, reducing the scrap rate for the stamping of the BMW 5 Series side panels from 8% to 1.2%.

Laser Welding Compatibility

We have developed a specialized laser welding coating that achieves weld strength ≥95% of the parent material in Audi A4 door welding, increasing efficiency by 300% compared to traditional resistance welding.

3. Service-Level Customization

Digital Color Management

A dedicated automotive color library has been established, encompassing over 2,000 RAL colors and over 100 special effect colors. Using an X-Rite Ci7800 spectrophotometer, color accuracy of ΔE <0.5 is achieved.

Full Lifecycle Traceability

Using QR code printing technology, a 16-digit code containing the substrate batch, coating formula, and production date is printed on the edge of each color-coated roll, enabling full traceability from the steel mill to the OEM.

IV. Future Trends and Innovation Directions

4D Printed Color-Coated Coils

Programmable temperature-controlled coatings enable intelligent display of patterns that change with temperature. This has been demonstrated in concept vehicles, with a temperature response range of 15-35°C.

Bionic Structural Coatings

Mimetic to the surface microstructure of shark skin, color-coated coils have been developed that reduce wind resistance by 12%, resulting in an 8% increase in driving range in the Mercedes-Benz EQXX concept car.

Blockchain Material Certification

We collaborated with IBM to develop a blockchain traceability system. The raw material procurement, process parameters, and quality inspection reports for each batch of color-coated coils are stored on-chain, ensuring compliance with IATF 16949 quality management system requirements.

V. Conclusion

The customized application of color-coated coils in the automotive manufacturing industry is shifting from a single material supply to a full value chain solution. Through the deep integration of materials science, digital technology, and environmental protection concepts, this not only meets the demand for lightweight and personalized vehicles, but also drives the entire industry chain towards higher added value. In the future, with innovative breakthroughs in intelligent surface technology and bio-based coatings, color-coated coils are bound to bring even more revolutionary changes to the automotive manufacturing industry.