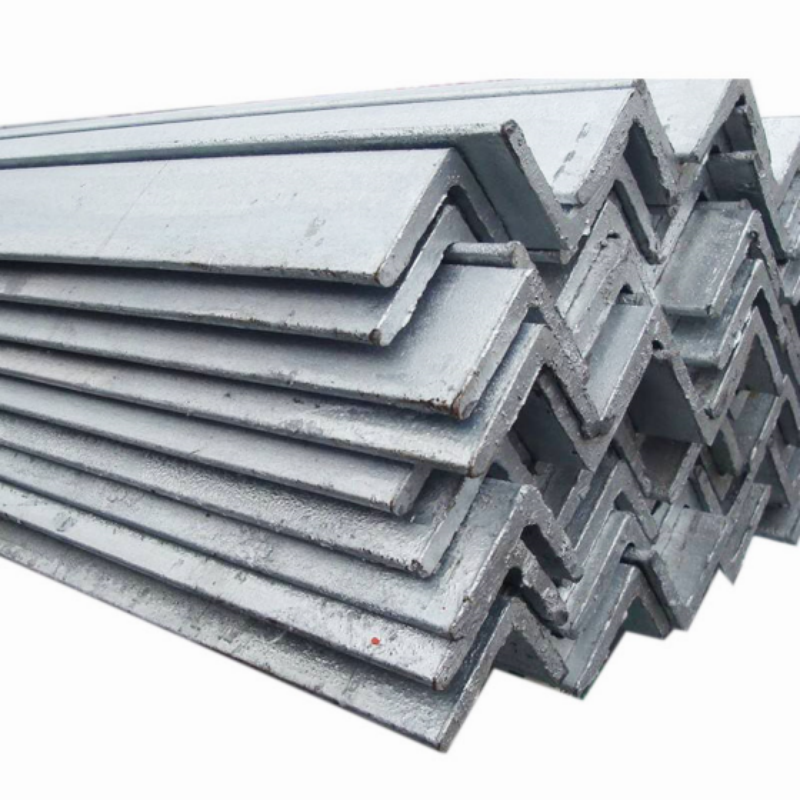

Products Description

| Product Name | galvanized angle steel |

| Place of Origin | China |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, etc. |

| Material | A36,St37,S235J0,S235J2,St52,16mn,S355JOQ195,Q215,Q235B, Q345B,S235JR,S355JR,S355,SS440, etc. |

| Length | 6m, 9m, 12mor according to customer requirements |

| Width: | 15-400mm |

| Thickness: | 1-30mm |

| Surface treatment | Galvanized, painted; or according to your requirements |

| Package | Standard packaging or as per customer's requirements |

| Price term | Ex-Work, FOB, CNF, CFR, CIF, FCA, DDP, DDU, etc. |

| Payment term | T/T , L/C, Western Union |

| Delivery Time | Within 7-15 days after we confirm you requirement. |

| Application | Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

| Contact | If you have any question, please feel free to contact me. We are sure your inquiry or requirements will get prompt attention. |

Galvanized angle steel is a steel product that is galvanized on the surface of the angle steel. The galvanizing treatment significantly improves its corrosion resistance and service life.

1. Basic features

Material: Usually made of hot-rolled or cold-rolled high-quality carbon structural steel (such as Q235, Q345, etc.). These steels have good mechanical properties and processability.

Galvanizing method: The hot-dip galvanizing process is mainly used. The angle steel is immersed in molten zinc liquid, so that the zinc and the surface of the angle steel are metallurgically bonded to form a strong and dense galvanized layer.

Sectional shape: Angle steel has an L-shaped or equilateral cross-section. The two vertical sides are called limbs, and the angle between them is 90 degrees or a customized angle. Cross-sectional dimensions (such as side length, thickness, etc.) are customized according to standards or customer needs.

2. Advantages

Strong corrosion resistance: The galvanized layer can effectively isolate the angle steel from direct contact with the corrosive environment, thereby extending its service life.

Low maintenance costs: Maintenance and replacement costs due to corrosion are reduced due to the protection of the galvanized layer.

Beautiful appearance: The galvanized layer has a smooth surface and uniform color, which improves the overall beauty of the product.

Good processing performance: Galvanized angle steel is easy to cut, weld, drill and other processing operations, and is convenient for on-site installation and construction.

3. Application areas

Construction field: used for supports, beams, columns, frames, window frames, door frames and other components in building structures.

Electric power and communications industry: As an integral part of infrastructure such as towers, poles, brackets, etc.

Machinery manufacturing: used to manufacture support structures, connectors and components for various mechanical equipment.

Transportation: Used to make support and connection structures for bridges, tunnels, rail transit and other transportation facilities.

Other fields: It is also widely used in petrochemical, marine engineering, agricultural facilities and other industries.

OUR ADVANTAGE

10+ YEARS EXPORT

10+ YEARS EXPORT QUALITY CERTIFICATES

QUALITY CERTIFICATES SERVICE FIRST

SERVICE FIRST INNOVATIVE DEVELOPMENT

INNOVATIVE DEVELOPMENT INNOVATION LEADS

INNOVATION LEADS EXPORT VOLUME

EXPORT VOLUME

WhatsApp

WhatsApp E-mial

E-mial