Products Description

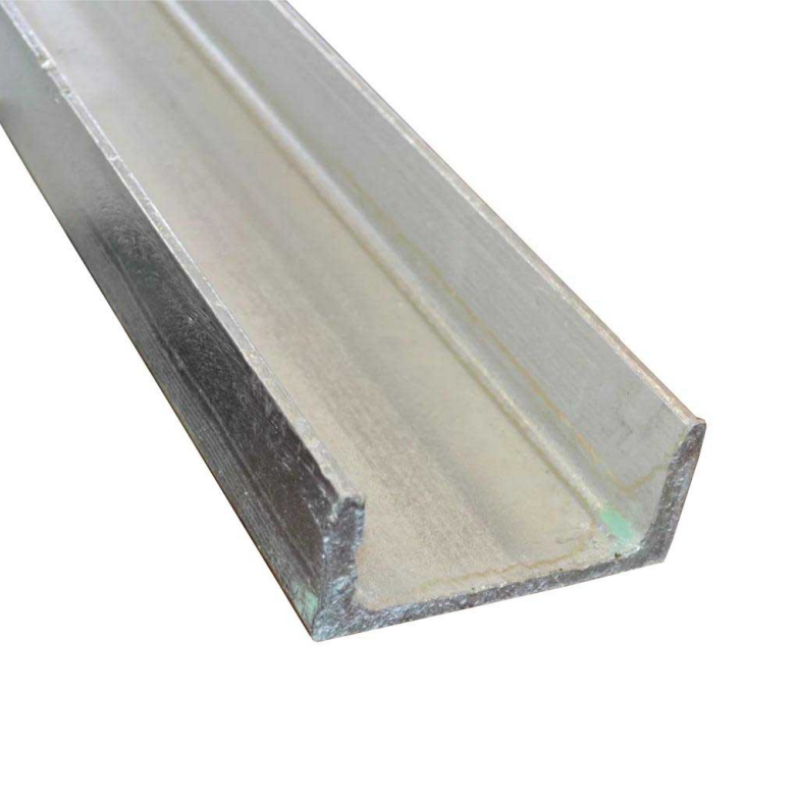

| Product Name | Galvanized Steel Channel |

| Length | 6m, 9m, 12m Or As Your Requirement |

| Standard | JIS, GB, ASTM, EN, DIN |

| Technique | Hot / Cold Rolled |

| Application | Construction structure |

| Supply Ability | 1000 tons per day |

| Payment | TT LC DP |

| Products Advantages | 1. High Quality 2. High Dimensional Accuracy 3. Cost Savings |

Galvanized channel steel is a steel product that is galvanized on the surface of the channel steel to enhance its corrosion resistance and extend its service life.

1. Basic features

Material: Usually made of hot-rolled or cold-rolled high-quality carbon structural steel (such as Q235, Q345, etc.), which is then galvanized after forming.

Galvanizing method: The hot-dip galvanizing process is mainly used, that is, the channel steel is immersed in molten zinc liquid, and a uniform and dense zinc layer is formed on the surface of the channel steel through chemical reaction.

Cross-sectional shape: Channel steel has a unique groove shape for easy connection and fixation with other components. Its cross-sectional dimensions (such as waist height, leg width, waist thickness, etc.) are customized according to standards or customer needs.

2. Advantages

Strong corrosion resistance: The galvanized layer can effectively prevent the channel steel from direct contact with corrosive media such as air and water, significantly improving the corrosion resistance of the channel steel.

Long service life: Due to the protective effect of the galvanized layer, the service life of galvanized channel steel is much longer than that of ungalvanized channel steel.

High aesthetics: The galvanized layer has a smooth surface and uniform color, which can improve the overall aesthetics of the product.

Good mechanical properties: Galvanized channel steel retains the original excellent mechanical properties of channel steel, such as high strength and good toughness.

3. Application areas

Construction field: widely used in beams, columns, supports, purlins and other components in steel structure buildings, as well as decorative lines and frames for building exterior walls.

Transportation field: used to make support structures and connectors for bridges, tunnels, highways and other transportation facilities.

Electric power field: used as support components and connectors for power facilities such as transmission towers and substations.

Machinery manufacturing field: used to manufacture support structures, frames, etc. for various mechanical equipment and equipment.

Other fields: It is also widely used in petrochemical, shipbuilding, mining machinery and other industries.

OUR ADVANTAGE

10+ YEARS EXPORT

10+ YEARS EXPORT QUALITY CERTIFICATES

QUALITY CERTIFICATES SERVICE FIRST

SERVICE FIRST INNOVATIVE DEVELOPMENT

INNOVATIVE DEVELOPMENT INNOVATION LEADS

INNOVATION LEADS EXPORT VOLUME

EXPORT VOLUME

WhatsApp

WhatsApp E-mial

E-mial