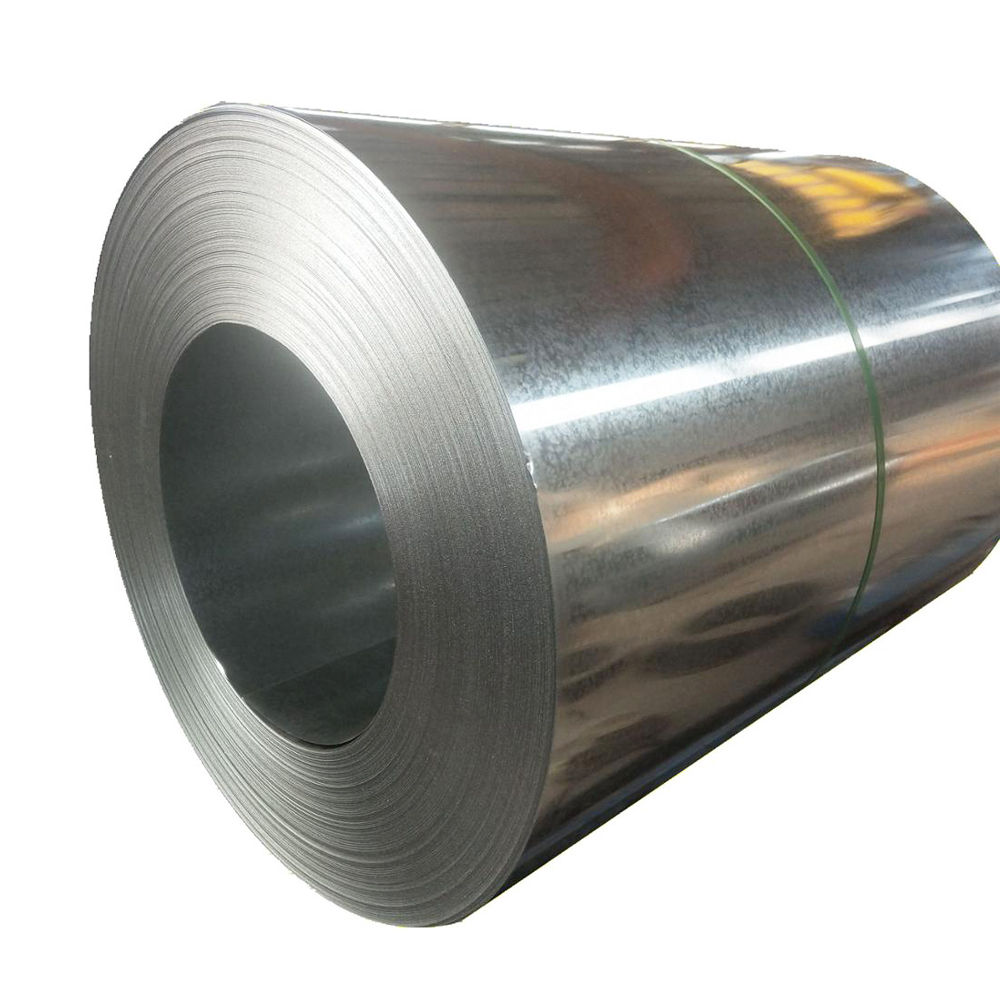

Products Description

DC01 galvanized coil is a surface galvanized sheet with yield strength of 235MPa.

Galvanized coil, a thin steel sheet that is dipped into a molten zinc bath to adhere a layer of zinc to its surface. It is mainly produced by the continuous galvanizing process, in which rolls of steel sheet are continuously dipped into a bath of molten zinc to make galvanized steel sheet; alloyed galvanized steel sheet. This steel sheet is also manufactured by the hot dipping method, but immediately after leaving the bath, it is heated to about 500°C to produce an alloyed coating of zinc and iron. This type of galvanized coil has good paint adhesion and weldability.

Product name: | Galvanized Steel Coils |

Place of Origin: | China |

Type: | Hot dipped/Electric Steel Coil |

Standard: | AISI, ASTM, BS, DIN, GB, JIS |

Certificate: | ISO9001 |

Grade: | SPCC,SPCD,SPCE/DC01.DC02.DC03/ST12,Q195.Etc |

Thickness: | 0.1-5.0mm |

Surface structure: | anti-finger print /skin pass/oiled/ dry/chromated |

Size: | Customized according to customer needs |

Tolerance: | ±1% |

Processing Service: | Bending, Welding, Decoiling, Cutting, Punching, Welding |

Invoicing: | by actual weight |

Delivery Time: | 7-15 days |

Technique: | Hot Rolled, Cold Rolled |

Port: | Tianjin/Qingdao or according to your requirement |

Packaging Details | in bundles, in bulk, customized packing. |

Chemical composition

Standard | Grade | C | Si | Mn | P | S | Ti |

Forcold forming Chinese Standard | DX51D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

DX52D With | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX53D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX54D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX56D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX57D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

Forcold forming Japanese Standard | SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

SGCD1 | 0.12 | 0.50 | 0.60 | 0.040 | 0.030 | 0.025 | |

SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

ForStructure Japanese Standard | SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

SGC400 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.150 | |

SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

ForStructure AISI Standard | S220GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

S250GD With | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S280GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S320GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S350GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

S550GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Mechanical properties

Grade | Yield strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

S220GD Z/ZM/AM | 220 | 300 | 20 |

S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

S280GD Z/ZM/AM | 280 | 360 | 18 |

S300GD A/AM | 300 | 380 | 18 |

S320GD Z/ZM/AM | 320 | 390 | 17 |

S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

S450GD A/AM | 450 | 480 | 15 |

S550GD Z/ZM/AZ/AM | 550 | 550 | - |

Galvanized surface selection

Zero Spangle | Minimized Spangle | Normal Spangle | Large Spangle |

|

|

|

|

OUR ADVANTAGE

10+ YEARS EXPORT

10+ YEARS EXPORT QUALITY CERTIFICATES

QUALITY CERTIFICATES SERVICE FIRST

SERVICE FIRST INNOVATIVE DEVELOPMENT

INNOVATIVE DEVELOPMENT INNOVATION LEADS

INNOVATION LEADS EXPORT VOLUME

EXPORT VOLUME

WhatsApp

WhatsApp E-mial

E-mial