Products Description

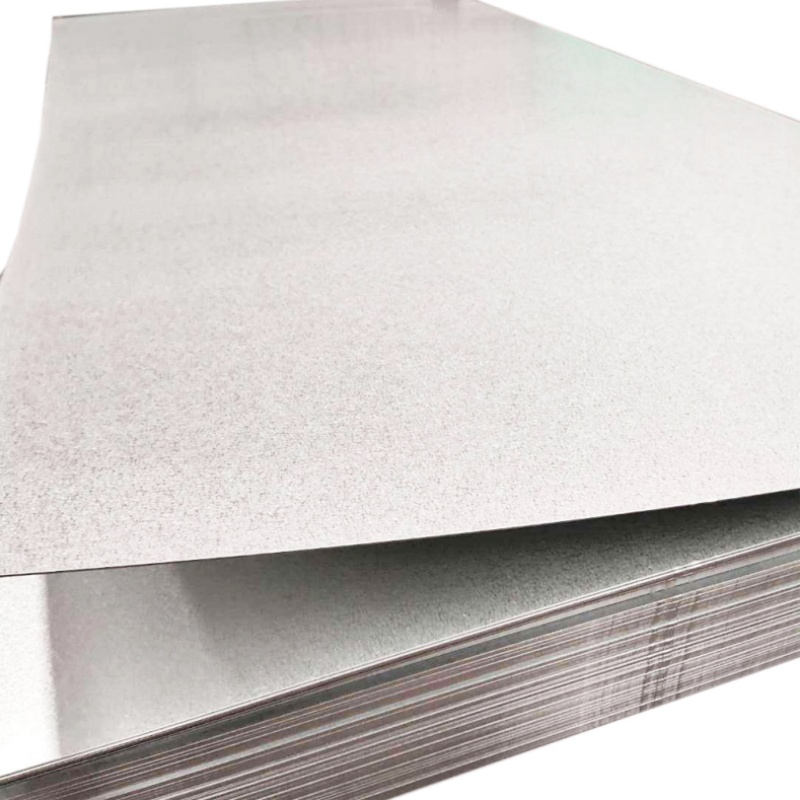

AZ150 Galvalume Steel Sheet Description

AZ150 is a hot-dip aluminum-zinc alloy coated steel. The resulting coating has excellent corrosion resistance and can be used in harsh environments. This combination produces a durable and corrosion-resistant material that can be used in any application with high strength or hardness.

Once the sheet is exposed to electrolyte or moisture, another coating may form a galvanic cell. This exposure results in spillage of zinc ions and corrosion protection of the exposed steel. AZ150 aluminized zinc is a high-quality, corrosion-resistant alloy commonly used in the construction and transportation industries. It has strong anti-rust, anti-oxidation and anti-corrosion capabilities, and is an option for those who need to transport items or expose items to severe weather conditions.

Scope of Application

Construction industry: such as roof, internal and external wall panels, sound insulation walls, pipes, garages, etc.

Automotive industry: such as mufflers, exhaust pipes, wiper accessories, fuel tanks, truck containers, etc.

Household appliances: such as refrigerator backplane, air conditioner, microwave oven, LED backlight, electric cabinet, etc

Agricultural use: such as greenhouse, granary, pig farm, chicken coop, etc

Other industries: such as heat exchangers, dryers, etc.

Product Parameters

|

Product Name |

AZ150 Galvalume Steel Sheet |

|

Thickness |

0.12mm-6.00mm |

|

Width |

600mm-1500mm |

|

Length |

1m-12m, Support Customization |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

|

Thickness of Aluminum Zinc Coating |

30-185g/m² |

|

Content of Al-Zn Coating |

Al: 55%, Zn: 43.5%, Si: 1.5% |

Chemical Composition

|

Al |

Zn |

Si |

Fe |

Cu |

Cd |

Pb |

Sn |

Ni |

Close Cr |

|

55-58 |

41-43 |

1.5-2 |

0.25 |

0.03 |

0.05 |

0.01 |

0.05 |

0.05 |

0.05 |

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD Z/ZM/AM |

220 |

300 |

20 |

|

S250GD Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD Z/ZM/AM |

280 |

360 |

18 |

|

S300GD A/AM |

300 |

380 |

18 |

|

S320GD Z/ZM/AM |

320 |

390 |

17 |

|

S350GD Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD A/AM |

450 |

480 |

15 |

|

S550GD Z/ZM/AZ/AM |

550 |

550 |

- |

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

|

Type of Coating |

Recommended Coating Weight |

|

Aluminum-zinc Alloy |

30/40/50/60/75/90/100/150 |

|

A: Coating quality50g/㎡,approximately equal to the coating thickness13.3pm |

|

|

Project |

Classification |

Symbol |

|

Type of Coating |

Aluminum-zinc Alloy |

AZ |

|

Surface Finish |

Conventional Sequins |

R |

|

Minimize Sequins |

M |

|

|

Skin Through |

S |

|

|

Surface Treatment |

Chromate Passivation |

c |

|

Non-chromate Passivation |

C5 |

|

|

Chromate Passivationoiling |

CO |

|

|

Chromium-free Passivationoiling |

CO5 |

|

|

Anti-fingerprint |

N |

|

|

Chromate-free/Anti-fingerprint |

N5 |

|

|

No chromate high weather resistance fingerprint |

NW |

|

|

Oil filling |

0 |

|

|

No treatment |

U |

Material Comparison

|

Chinese Standard |

European Standards |

American Standard |

Japanese Standard |

|

DC51D+AZ |

DX51D+AZ |

CS Type B, Type C |

SGLCC |

|

DC52D+AZ |

DX52D+AZ |

DS |

SGLCD |

|

S250GD+AZ |

S250GD+AZ |

255 |

- |

|

S300GD+AZ |

- |

- |

- |

|

S350GD+AZ |

S350GD+AZ |

345 |

Class1 SGLC490 |

|

S550GD+AZ |

S550GD+AZ |

550 |

SGLC570 |

OUR ADVANTAGE

10+ YEARS EXPORT

10+ YEARS EXPORT QUALITY CERTIFICATES

QUALITY CERTIFICATES SERVICE FIRST

SERVICE FIRST INNOVATIVE DEVELOPMENT

INNOVATIVE DEVELOPMENT INNOVATION LEADS

INNOVATION LEADS EXPORT VOLUME

EXPORT VOLUME

WhatsApp

WhatsApp E-mial

E-mial