1. What is galvanized coil?

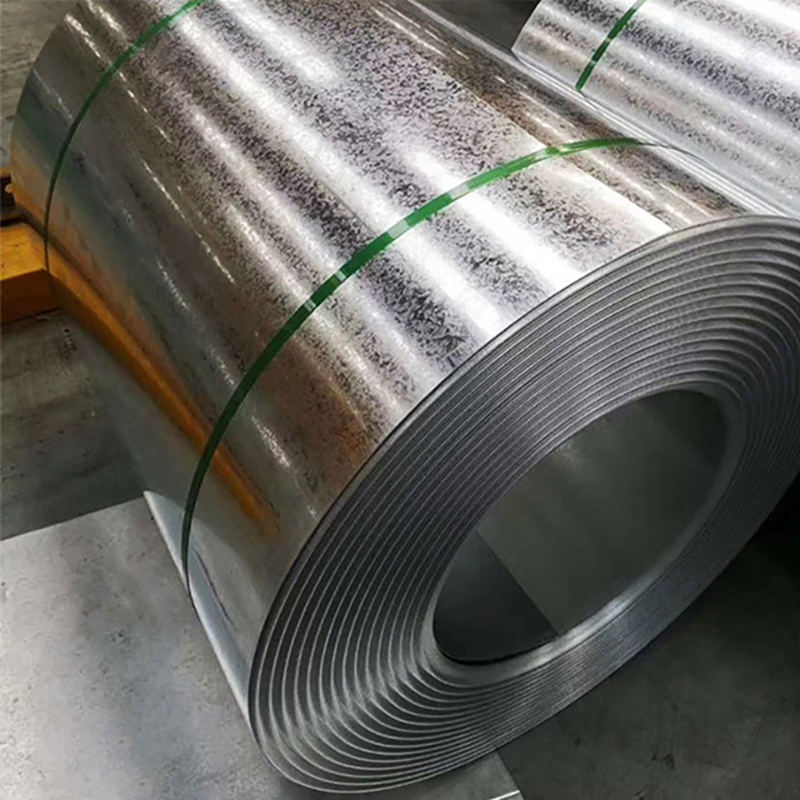

Galvanized coil is a metal material with a layer of zinc on the surface of the steel plate. The zinc layer can effectively protect the steel plate, prevent it from rusting and corrosion, and greatly extend the service life of the steel plate. Galvanized coil has been widely used in industrial production and construction due to its excellent performance and wide application.

2. Advantages of galvanized coil

① Excellent anti-corrosion performance: The zinc layer can form a dense oxide film, effectively isolate air and moisture, and prevent the steel plate from rusting.

② Strong wear resistance: The galvanized layer has good wear resistance and can extend the service life of the product.

③ Good welding performance: The galvanized coil has good welding performance and is easy to process into various shapes.

④ Beautiful appearance: The surface of the galvanized coil is smooth, with a silvery-white metallic luster, beautiful and generous.

⑤ Environmental protection: The galvanizing process does not produce harmful substances and meets environmental protection requirements.

3. Uses of galvanized coils

Galvanized coils are widely used and are mainly used in the following fields:

① Construction industry: Galvanized coils are widely used in roofs, walls, doors and windows, steel frames and other parts of buildings to play a decorative and protective role.

② Home appliance industry: Galvanized coils are used to manufacture the inner tank and outer shell of home appliances such as refrigerators, washing machines, and air conditioners.

③ Automobile industry: Galvanized coils are used to manufacture automobile bodies, chassis and other parts.

④ Machinery manufacturing industry: Galvanized coils are used to manufacture parts for various mechanical equipment.

⑤ Packaging industry: Galvanized coils are used to manufacture various packaging containers.

4. Selection of galvanized coils

When selecting galvanized coils, it is necessary to select the appropriate galvanizing method, zinc layer thickness and surface treatment according to different application occasions and requirements. Common galvanizing methods include hot-dip galvanizing and electro-galvanizing.

① Hot-dip galvanizing: Hot-dip galvanizing has a thicker zinc layer and excellent anti-corrosion performance. It is suitable for outdoor environments and occasions requiring high corrosion resistance.

②Electro-galvanizing: The electro-galvanizing zinc layer is thinner and is suitable for indoor environments and occasions with high requirements for appearance.

5. Conclusion

As a metal material with excellent performance and wide application, galvanized coil plays an important role in modern industry and construction. With the continuous advancement of science and technology, the performance and application areas of galvanized coils will continue to expand.

[Hebei Yehui Metal Materials Co., Ltd.] As a professional galvanized coil manufacturer, we have advanced production equipment and a professional technical team, and can provide customers with high-quality galvanized coil products. Welcome customers to consult!