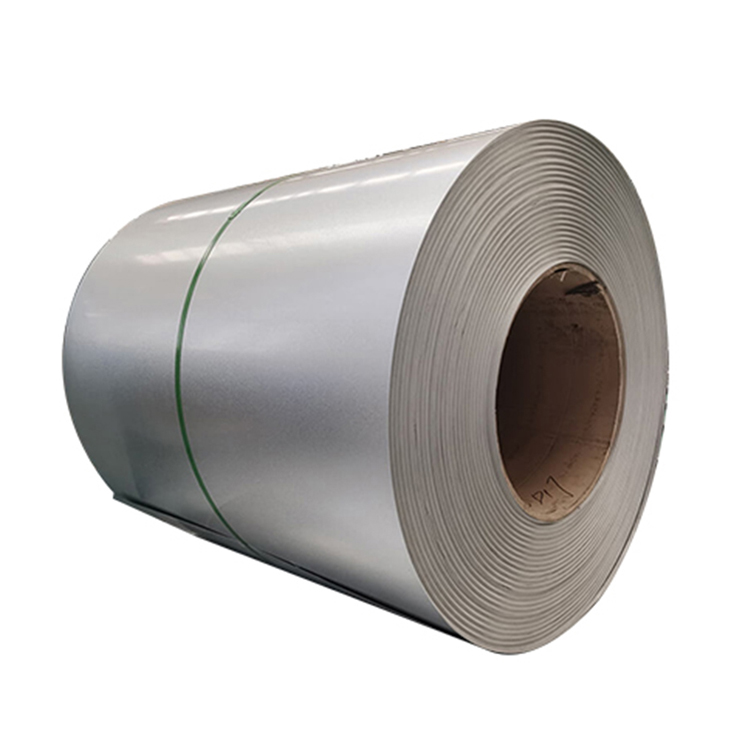

Products Description

Hot Dip Galvanized Coil DescriptionHot dip galvanizing is to make the molten metal react with the iron substrate to produce an alloy layer, so that the substrate and the coating are combined. Hot galvanizing is to pickle the steel and iron parts first. In order to remove the iron oxide on the surface of the steel and iron parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

|

Chemical composition

Standard | Grade | C | Si | Mn | P | S | Ti |

Forcold forming Chinese Standard | DX51D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

DX52D With | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX53D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX54D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX56D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

DX57D Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

Forcold forming Japanese Standard | SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

SGCD1 | 0.12 | 0.50 | 0.60 | 0.040 | 0.030 | 0.025 | |

SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

ForStructure Japanese Standard | SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

SGC400 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.150 | |

SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

ForStructure AISI Standard | S220GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

S250GD With | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S280GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S320GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

S350GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

S550GD Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Mechanical properties

Grade | Yield strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

S220GD Z/ZM/AM | 220 | 300 | 20 |

S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

S280GD Z/ZM/AM | 280 | 360 | 18 |

S300GD A/AM | 300 | 380 | 18 |

S320GD Z/ZM/AM | 320 | 390 | 17 |

S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

S450GD A/AM | 450 | 480 | 15 |

S550GD Z/ZM/AZ/AM | 550 | 550 | - |

Galvanized surface selection

Zero Spangle | Minimized Spangle | Normal Spangle | Large Spangle |

|

|

|

|

Scope of Application

For a long time, hot-dip galvanizing process has been favored by people because of its low plating cost, excellent protection characteristics and beautiful appearance. It is widely used in automobile, construction, household appliances, chemical industry, machinery, petroleum, metallurgy, light industry, transportation, electric power, aviation and marine engineering and other fields.

OUR ADVANTAGE

10+ YEARS EXPORT

10+ YEARS EXPORT QUALITY CERTIFICATES

QUALITY CERTIFICATES SERVICE FIRST

SERVICE FIRST INNOVATIVE DEVELOPMENT

INNOVATIVE DEVELOPMENT INNOVATION LEADS

INNOVATION LEADS EXPORT VOLUME

EXPORT VOLUME

WhatsApp

WhatsApp E-mial

E-mial